Automated Packaging Equipment:

Professional Solutions at the Highest LevelBESSEN – Your Trusted Manufacturer of Automated Packaging Equipment

BESSEN Specializes in Spiral Freezers, Chillers, Conveyors, Weighing Systems, Filling Machines, Bagging & Wrapping Systems, Metal Detectors, and Complete Food Processing & Packaging Machinery. Discover Unmatched Efficiency, Quality, and Innovation with BESSEN’s Customized Automated Packaging Solutions for Industrial Needs. Explore our Leading Packaging Equipment in the USA, Crafted for Exceptional Performance, Reliability, and Customer Satisfaction in the Food Processing and Packaging Industry. Trust BESSEN to Enhance Your Production Line with Premium Industrial Packaging Systems.

OUR BEST PACKAGING EQUIPMENT

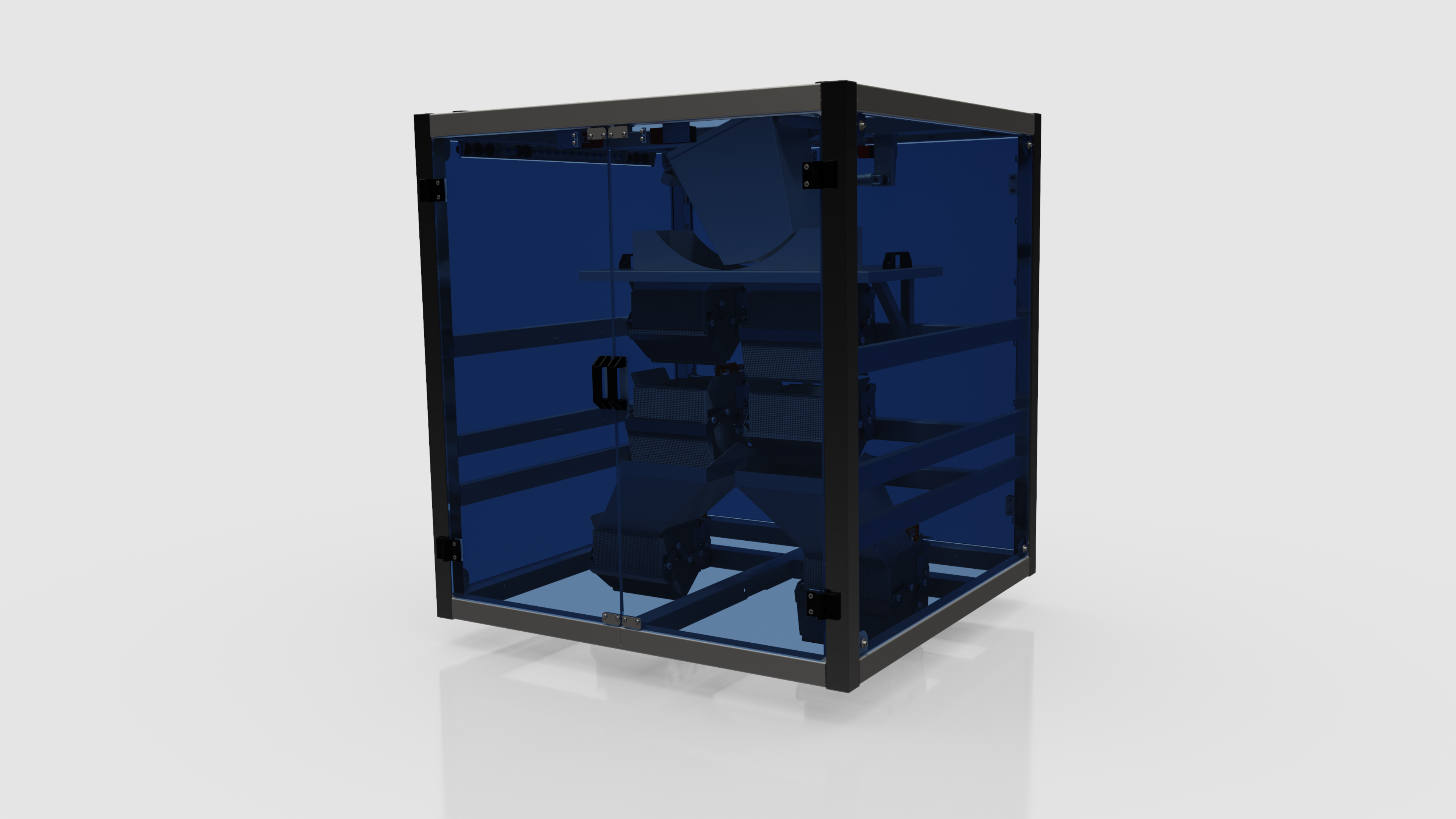

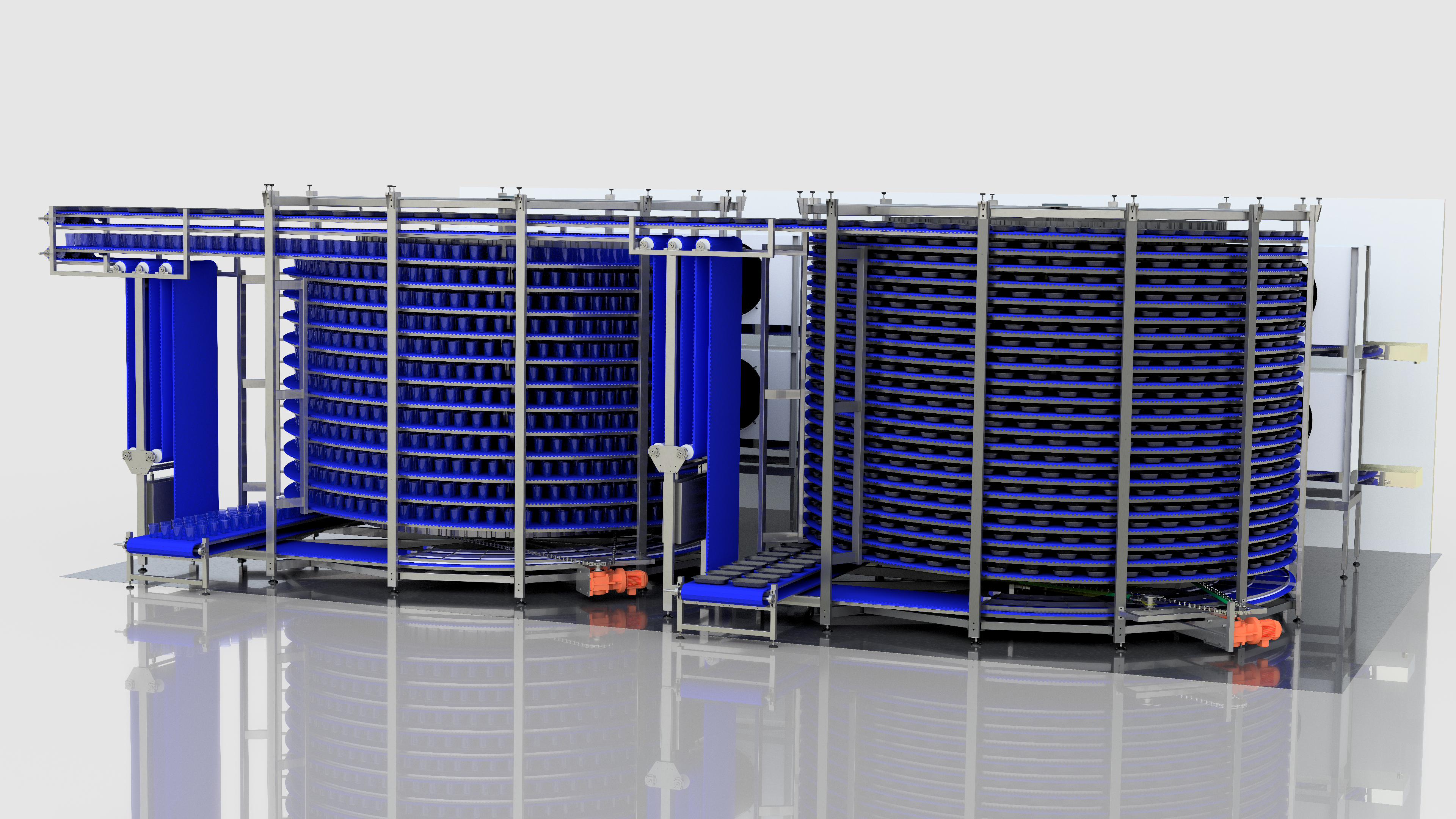

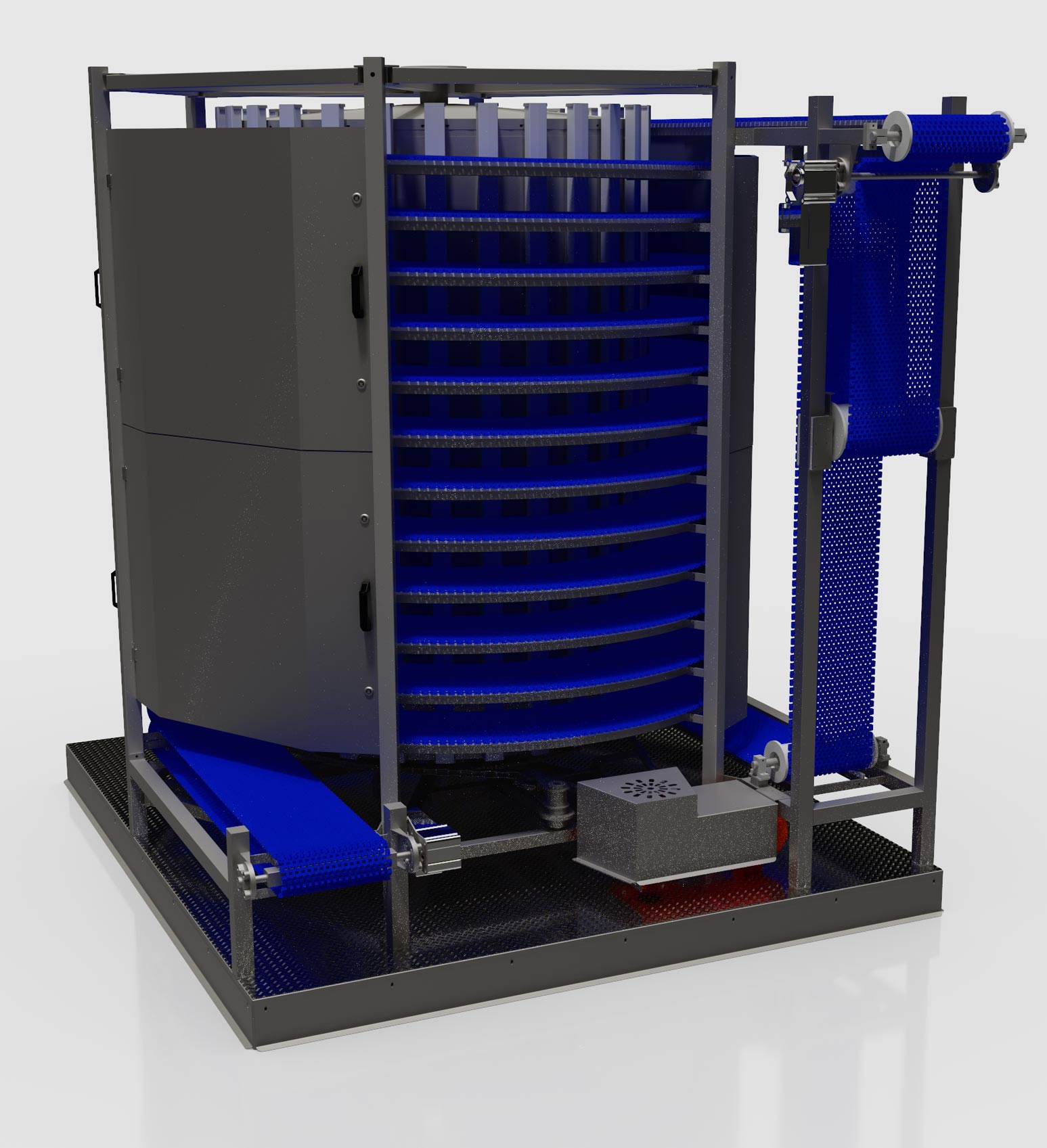

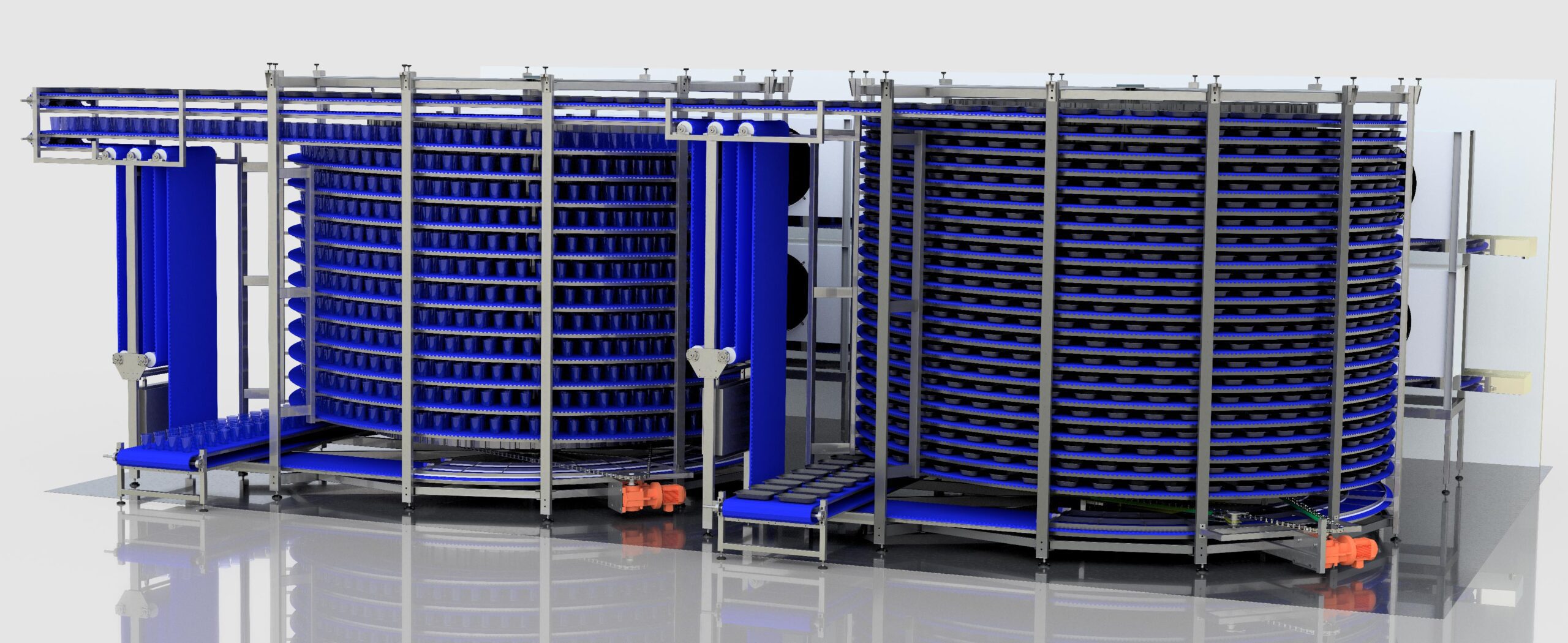

SPIRAL CONVEYORS

Spiral Chiller-Freezer Conveyor Systems

Each unit is custom-built with options for stainless steel or modular plastic belts, supporting applications from light loads to industrial-scale production. BESSEN offers single, dual, and multi-tier spiral configurations tailored to maximize space efficiency and production capacity.

Whether you’re optimizing a freezing tunnel or upgrading your packaging automation, BESSEN Spiral Conveyors provide reliable, hygienic, and energy-efficient solutions for demanding industries. Explore our fully customizable systems and elevate your production with smart spiral technology.

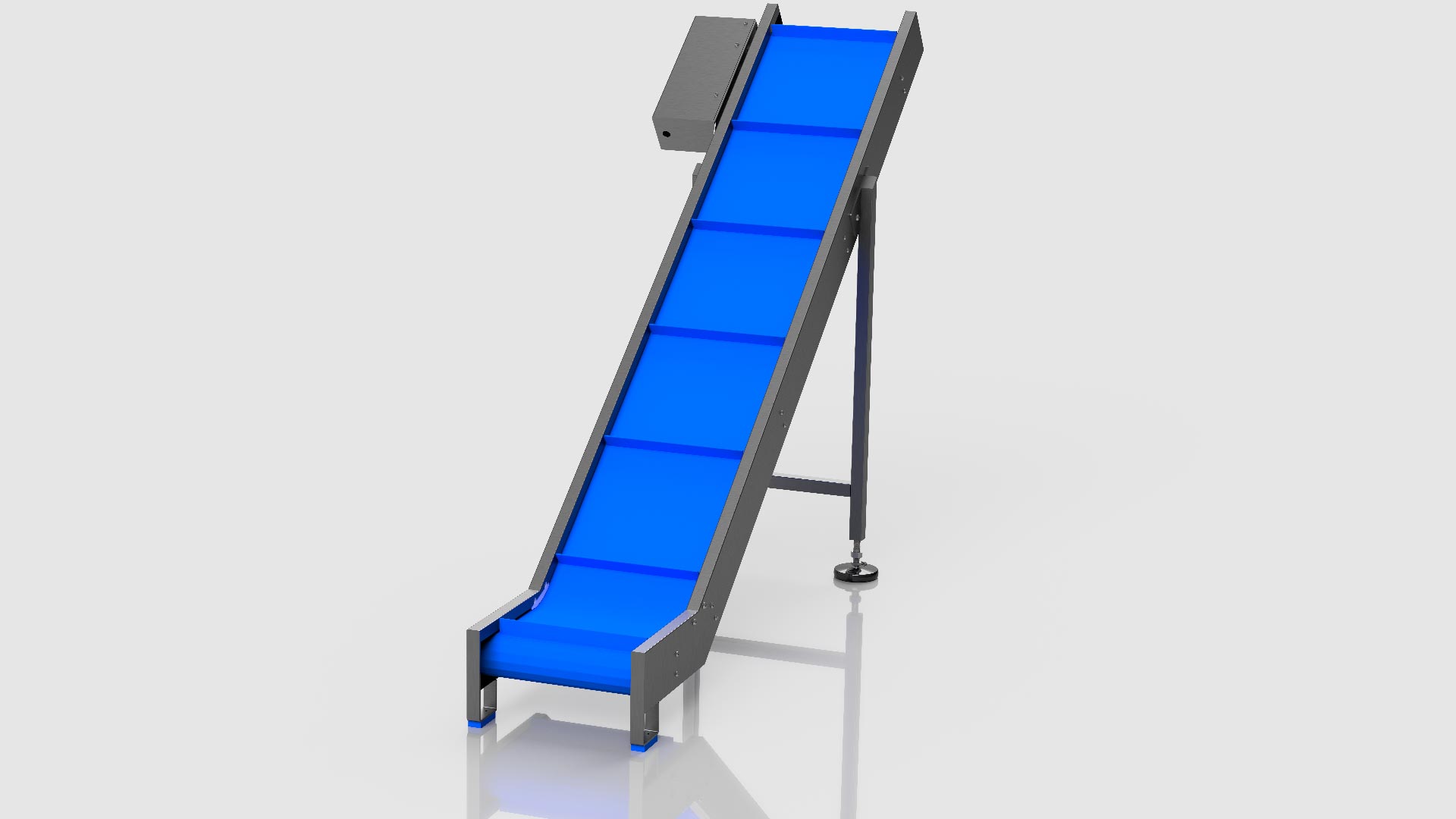

CONVEYORS

Conveyor Systems

Incline conveyors are available in various angles—including steep and vertical configurations—making them perfect for moving products between levels with minimal disruption. These systems are widely used in frozen food, snack, bakery, and meat processing environments.

Our take-away conveyors offer seamless product discharge from bagging, sealing, or thermoforming machines. With adjustable speeds and customizable lengths, they integrate easily into existing lines to reduce downtime and eliminate workflow bottlenecks.

Whether you're moving raw ingredients or packed goods, BESSEN Conveyors provide hygienic, space-saving, and cost-effective solutions tailored to your specific production needs.

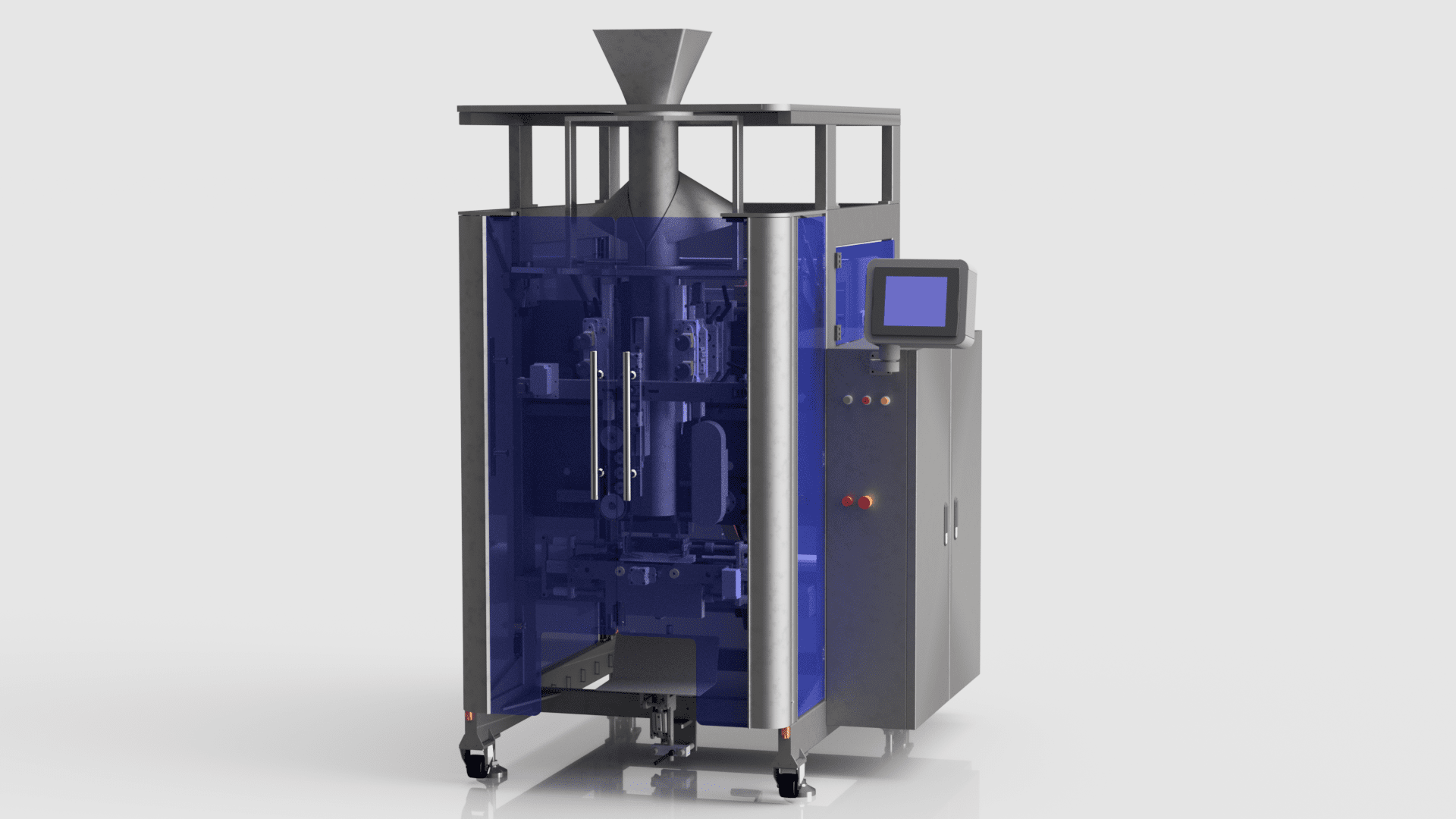

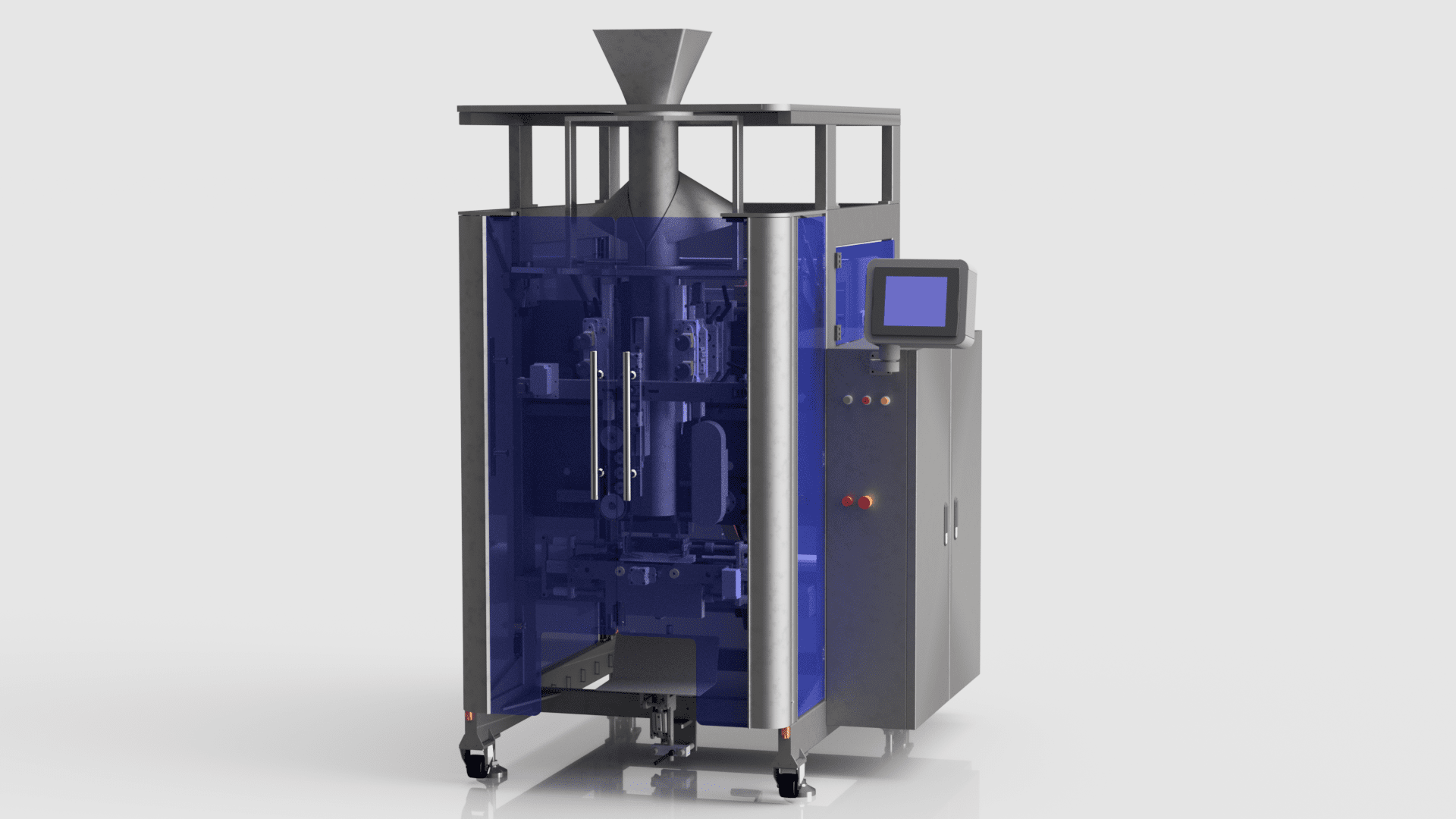

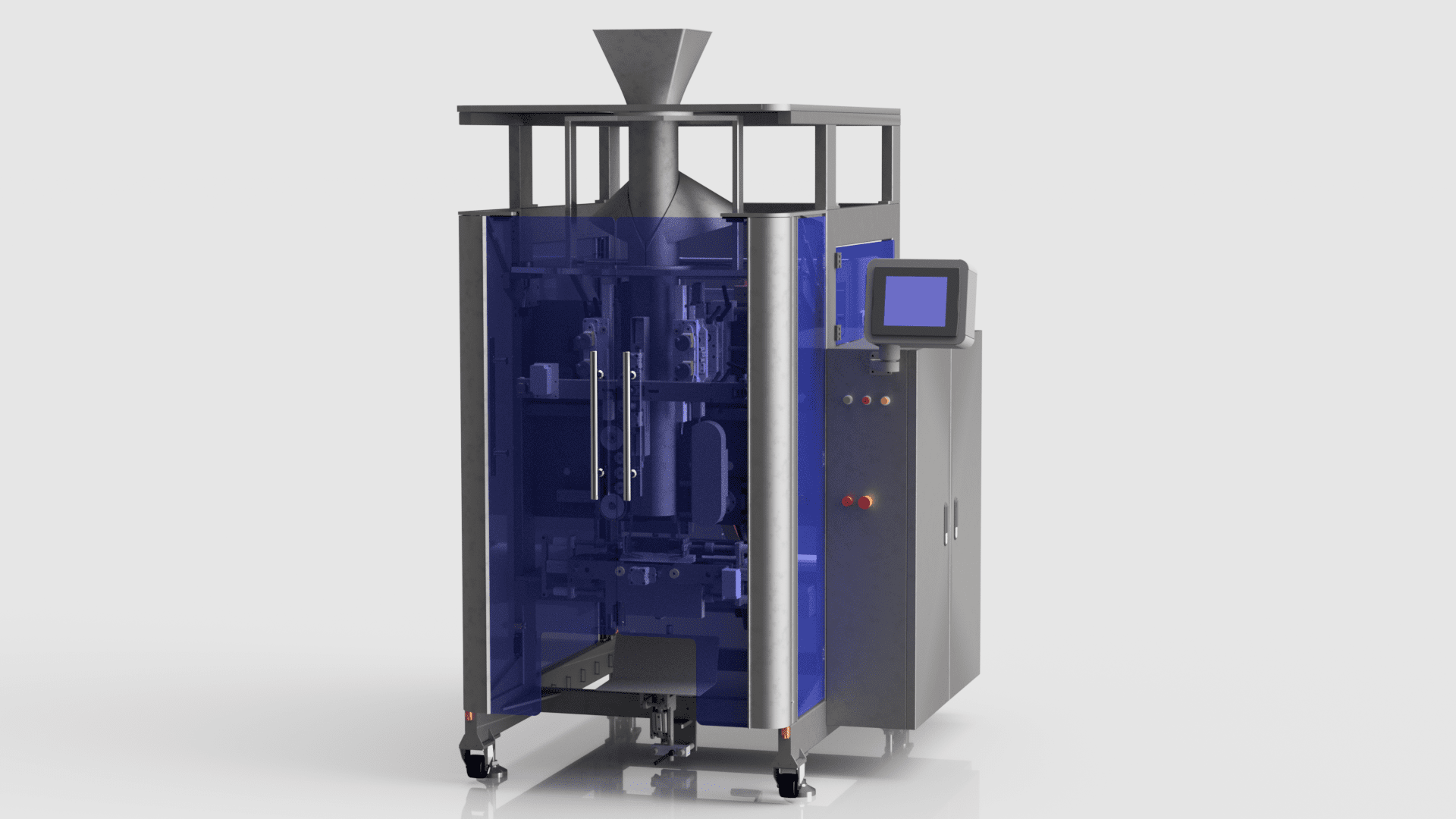

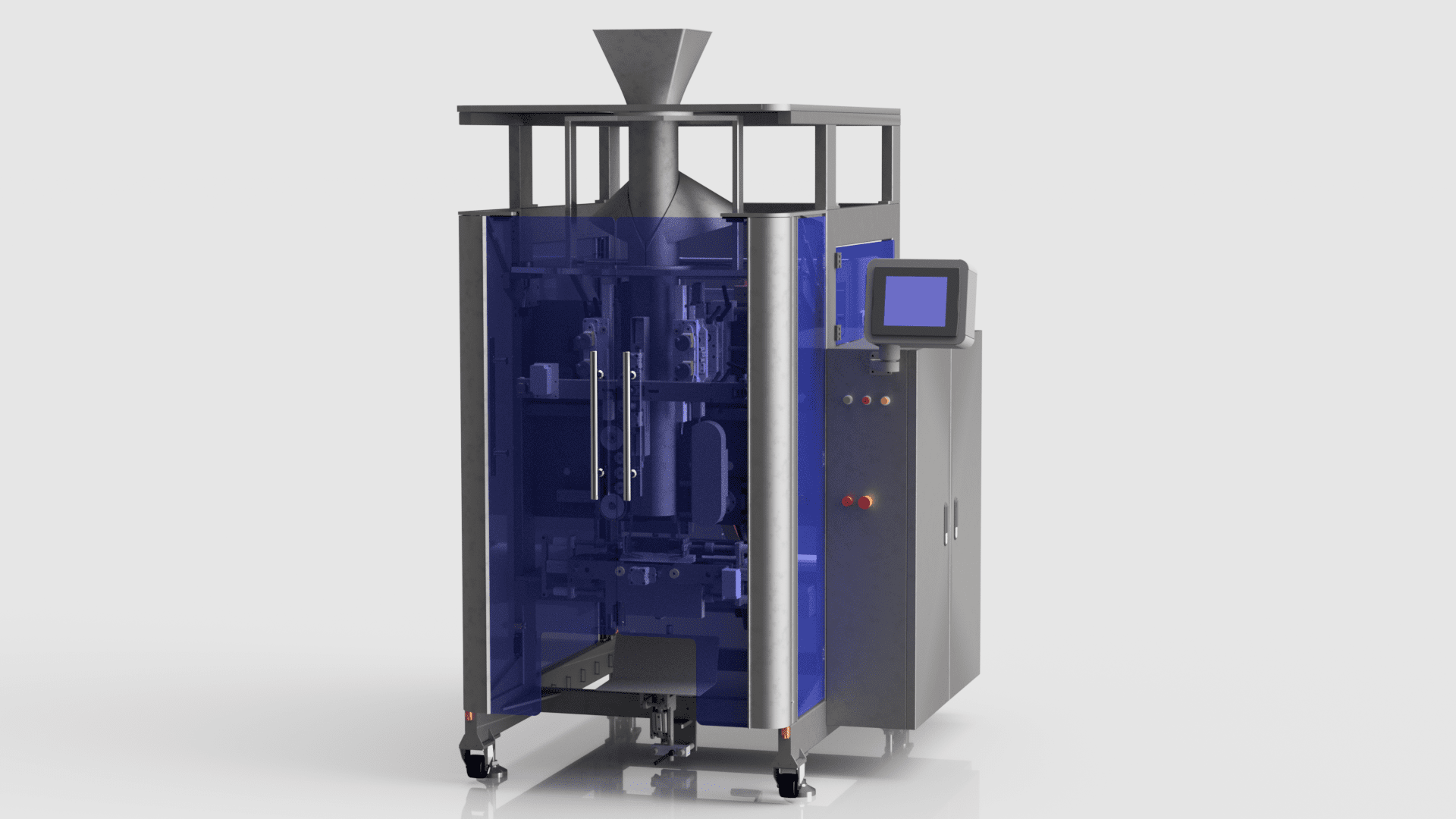

VFFS MACHINES & BAGGING MACHINES

VFFS Machines

Advanced options such as hole punching, tear notches, film tracking, end-seal cooling, and vacuum film assist enhance production capabilities. BESSEN VFFS machines are often paired with combination scales, auger fillers, vibratory feeders, and piston fillers for fully integrated packaging lines.

Whether you're packaging snacks, powders, grains, or frozen foods, our automated VFFS solutions ensure consistent seal quality, reduced waste, and streamlined operations. Trust BESSEN for tailored, cutting-edge vertical packaging systems.

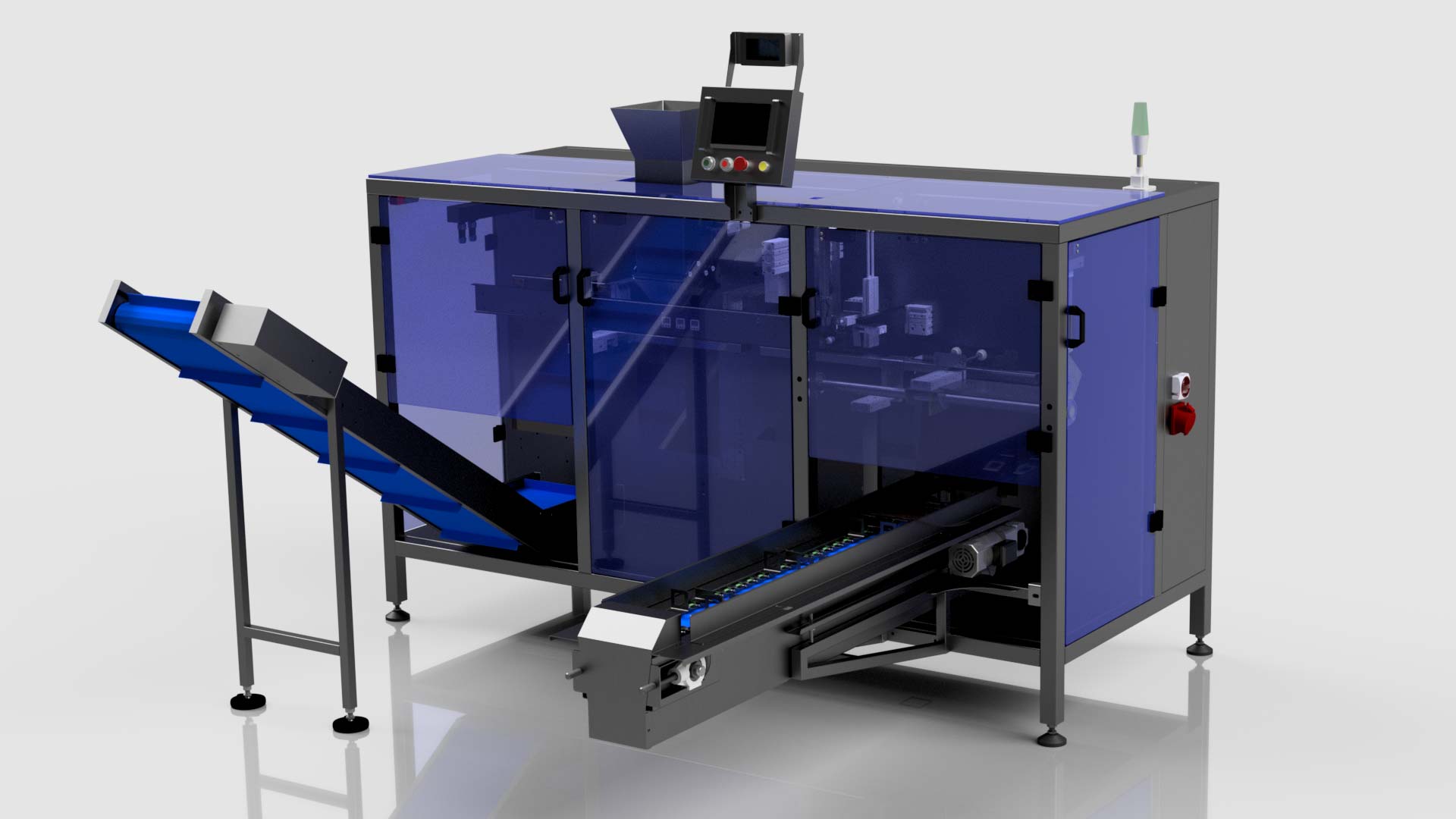

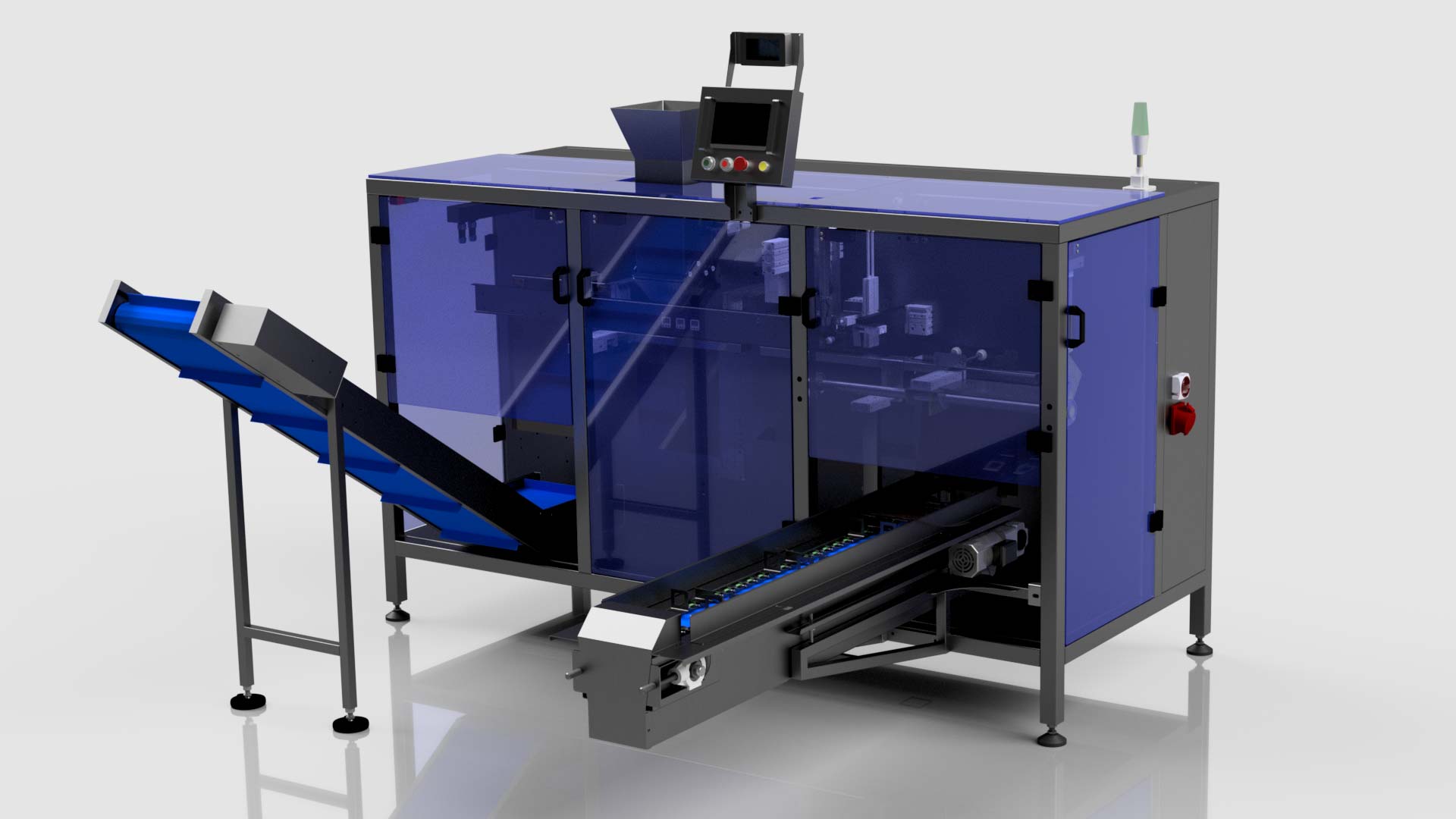

POUCH FILLING MACHINES

Pouch Filling Machines

The 100-Series is ideal for small to medium-scale operations, delivering speeds up to 19 bags per minute with outstanding precision. For larger production needs, the 500-Series provides robust performance at up to 33 bags per minute, perfect for packaging snacks, powders, frozen foods, and more.

All BESSEN pouch machines support zipper bags, stand-up pouches, flat pouches, and more—with easy changeover and intuitive controls. With advanced automation and durable construction, our pouch systems enhance line efficiency while maintaining superior packaging quality.

Explore BESSEN’s reliable premade pouch technology and take your packaging to the next level.

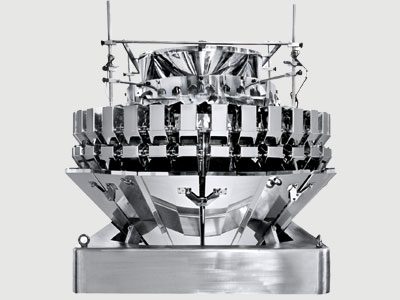

COMBINATION SCALES

Combination Scales

Our Smart Weigh Series—from 10 to 32 heads—handles a wide variety of products including meats, fish, cottage cheese, and granular items. Advanced high-speed load cells, intelligent multi-sampling, and real-time self-diagnostics guarantee consistent performance and streamlined maintenance.

Built to optimize your production line, BESSEN combination scales integrate seamlessly with form-fill-seal and pouch packaging machines. Discover how our weighing technology can elevate your packaging accuracy and line efficiency.

FLOW WRAPPERS

Flow Wrappers

Available in four size variants (250, 350, 450, and 600), the 250–600X series supports both manual and automatic loading. Built in painted steel or hygienic 304 stainless steel, each model can be customized with 2 VFD or 2 servo drive systems for optimized control and performance.

Whether you're wrapping soft items or non-conveyable goods, BESSEN Flow Wrappers deliver consistent results with high flexibility, reliability, and ease of integration into automated packaging lines. Elevate your packaging process with smart, adaptable flow wrapping technology.

WORKING PLATFORMS

Working Platform

The P1 Platform features full stainless-steel construction with a diamond plate surface. Customizable in size, height, and stair position, it offers a durable and secure solution for elevated equipment integration.

The P2 Platform includes an integrated washing system, allowing combination weigher components to be cleaned directly on the platform—eliminating the need for manual transport and improving daily sanitation routines.

BESSEN platforms combine structural integrity, ergonomic design, and hygienic innovation to streamline your packaging process. Optimize your workspace with modular support systems tailored to your operational needs.

TRAY SEALING MACHINES

Tray Sealing Machines

From the Smart 400 Tray Sealing Machine, ideal for high-capacity operations, to the compact and efficient Smart 200 Tray Sealing Machine, our equipment is designed to handle a variety of tray sizes, materials, and sealing requirements. BESSEN’s customizable options ensure seamless integration into your production line, providing maximum flexibility and performance.

With advanced features like Modified Atmosphere Packaging (MAP) capability, robust construction, and user-friendly operation, BESSEN Tray Sealing Machines are the perfect choice for improving production automation, enhancing product freshness, and ensuring consistent packaging quality. Contact us today to learn how our tray sealing systems can elevate your packaging process and meet your production goals.

FILLING LINES

Filling Lines

Choose between pneumatic-driven or high-accuracy servo-driven models. Servo models deliver exceptional precision with programmable pump speeds that reduce foaming and allow detailed filling profiles for each product. All lines are volumetric and can be tailored to customer-specific bottle dimensions.

Engineered with failure-safe features and customization flexibility, BESSEN filling lines ensure consistent fill levels, reduced product waste, and seamless integration with existing bottling operations. Discover high-performance, adaptable filling solutions that support your production efficiency and quality goals.

METAL DETECTORS

Metal Detectors

Horizontal metal detectors are ideal for conveyorized packaged goods, offering precise scanning to safeguard product integrity. Vertical detectors, perfect for gravity-fed or free-falling items, deliver high-sensitivity detection before packaging begins.

Each system is fully customizable with various conveyor types and automated rejection options to match your specific line requirements. Built to perform in demanding environments, BESSEN detectors help ensure compliance with global food safety standards.

Trusted by food manufacturers worldwide, BESSEN metal detection systems are a critical component in protecting your brand and delivering consistent quality assurance at every stage of production.

PRODUCT TRANSFER SYSTEMS

Product Transfers Systems

The T1 Transfer System is ideal for high-capacity, multi-lane distribution. Featuring motorized diverters and optional checkweighing integration, it seamlessly connects to thermoformers and form-fill-seal machines for large-scale production.

The T2 Transfer System is built for compact, two-lane configurations, handling free-flowing products such as powders, grains, and nuts. Its open-frame design supports vibratory or gravity-fed operation—ideal for packaging setups without thermoforming.

Whether you're routing bulk product or unit loads, BESSEN Transfer Systems deliver clean, efficient, and customizable solutions tailored to your production line.

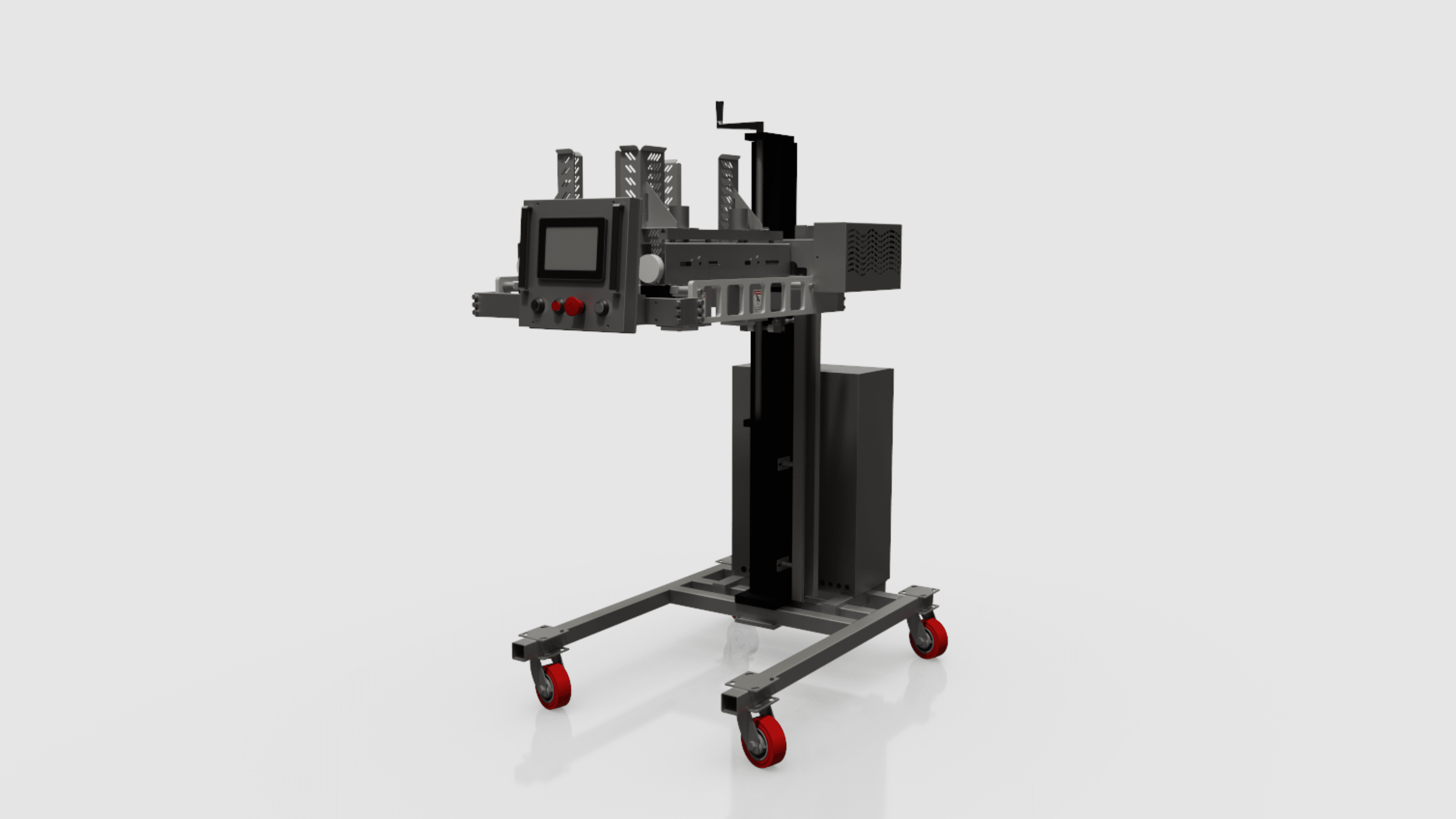

DENESTER MACHINES

Denester Machines

The adjustable stainless-steel magazine securely holds stacked trays, while a pneumatic or servo-driven mechanism ensures consistent high-speed dispensing—ideal for meat, seafood, ready meals, and bakery trays. Built from food-grade materials, the denester supports sanitary operations and easy maintenance.

Equipped with a touchscreen HMI, operators can easily control functions and perform quick changeovers. BESSEN denesters accommodate a wide range of tray formats and offer reliable, high-efficiency performance to streamline packaging and reduce manual labor.

PARFAIT MACHINE

Parfait Machine

The programmable multi-stage filling system accurately deposits yogurt, fruit purées, granola, or other ingredients into pre-formed cups, ensuring distinct, uniform layers with minimal waste. Built entirely from food-grade stainless steel, the parfait machine supports sanitary operations and easy cleaning.

Equipped with a touchscreen HMI, operators can easily adjust recipes, fill weights, and container sizes, enabling quick changeovers between different product SKUs. BESSEN Parfait Machines pair perfectly with BESSEN Denesters or tray handling systems to automatically position cups, streamlining the entire filling process.

Designed for dairy processors, dessert manufacturers, and co-packers, BESSEN parfait lines deliver consistent, high-quality products while reducing manual labor and maximizing throughput.

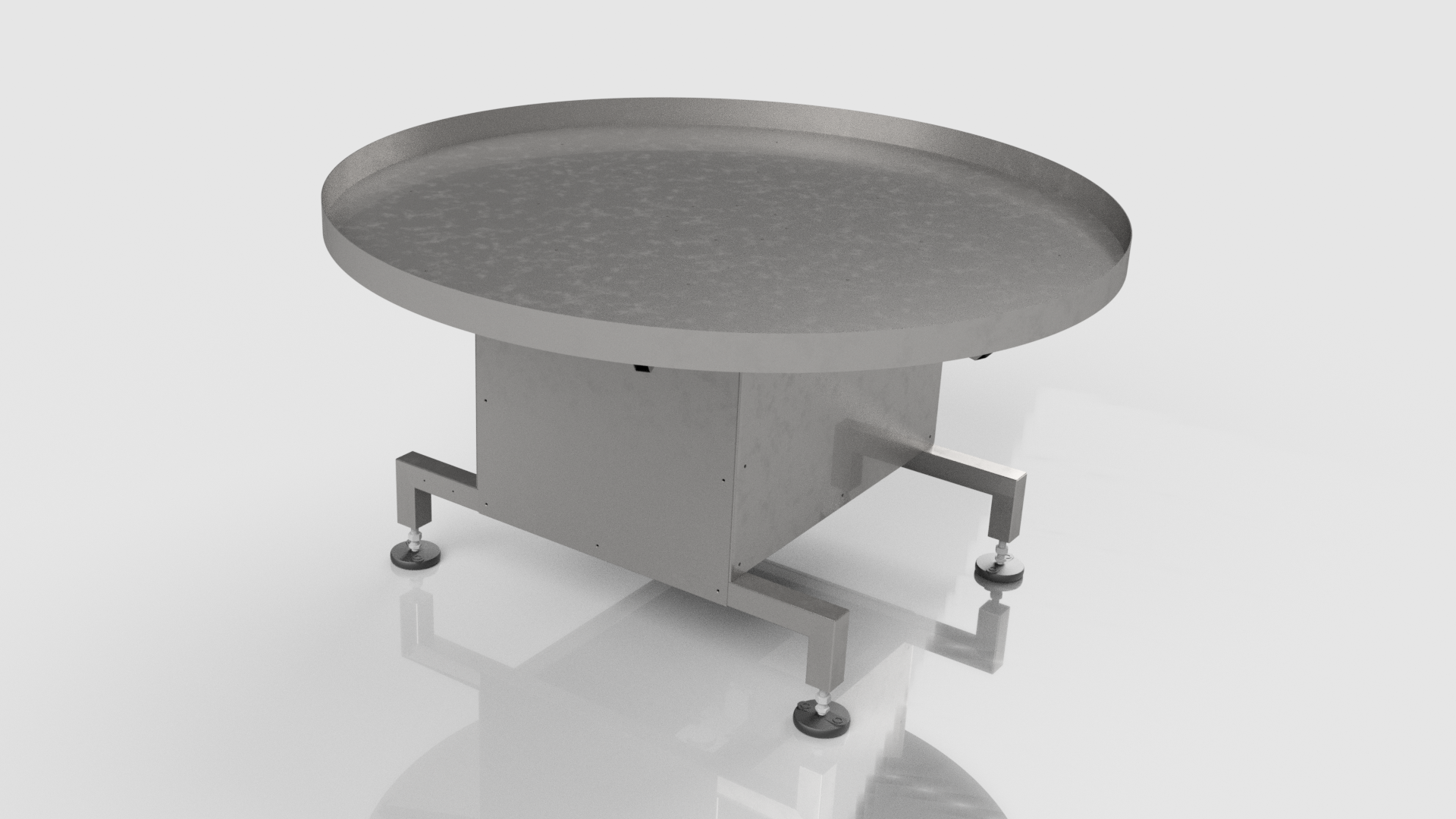

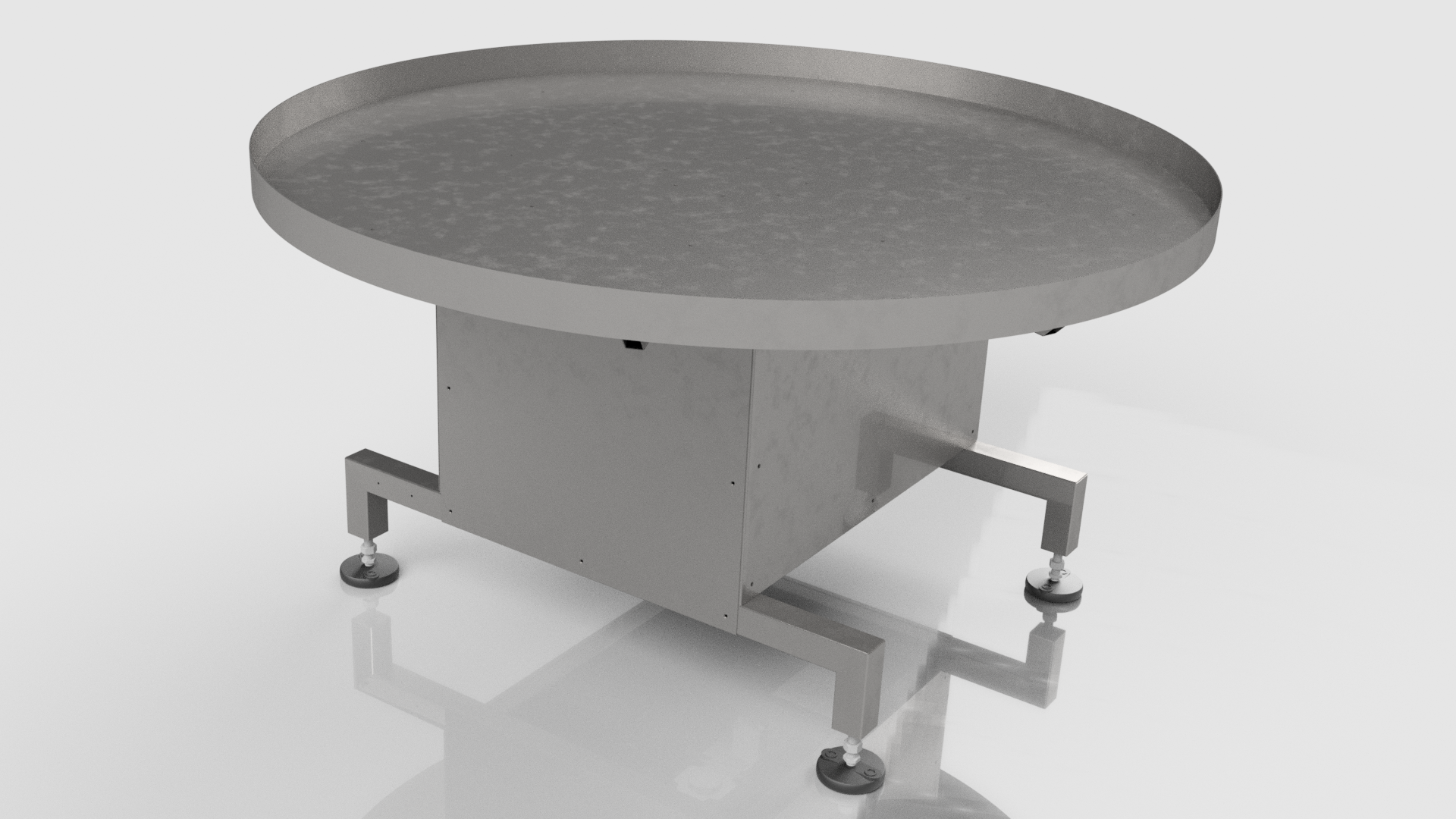

ACCUMULATION TABLE

Accumulation Table

Featuring a smooth stainless-steel rotary surface and adjustable speed controls, BESSEN accumulation tables gently manage finished products without damage—ideal for food, beverage, pharmaceutical, and industrial items. The compact design fits into tight production spaces, while the hygienic build ensures easy cleaning and compliance with food safety standards.

Operators can easily adjust the table's settings to match production speeds, while stable legs or optional casters allow flexible positioning across the facility. Integrated into packaging lines or used as standalone units, BESSEN accumulation tables enhance productivity, reduce downtime, and support smooth end-of-line handling.

BESSEN PACKAGING LINES

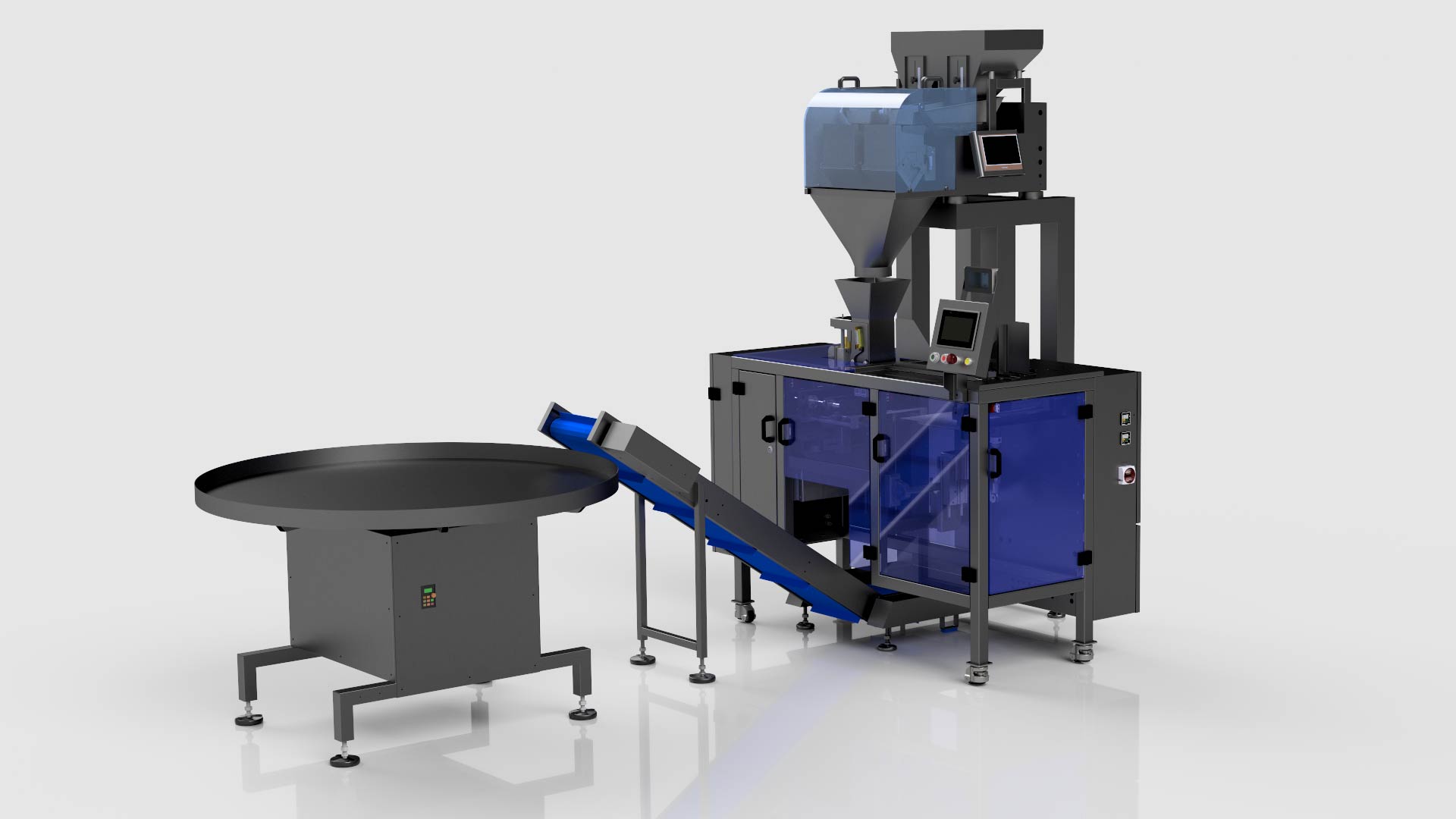

Packaging Line With VFFS Machine

Packaging Line With VFFS Machine

Packaging Line With Pouch Machine

Packaging Line With Pouch Machine

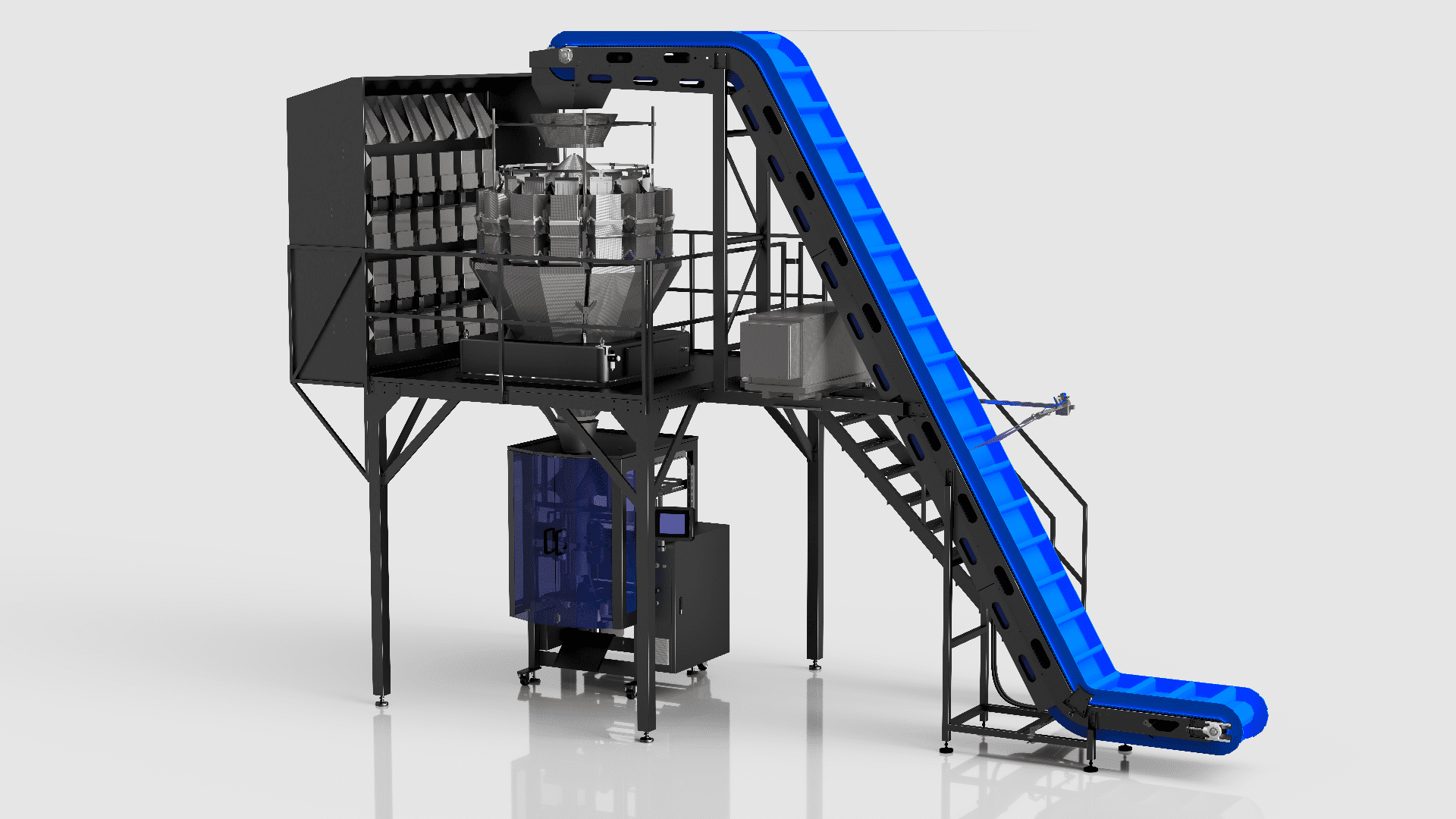

Cascade Packaging Line

Cascade Packaging Line

The line can include: Product Loader, Incline Conveyor, Combination Scale, Incline Conveyor, VFFS Machine, Take-Away Conveyor, and Rotary Accumulation Table. Depending on your product and production needs, the equipment configuration can be customized — we offer alternative modules and layout options to meet specific requirements.

All equipment is proudly made in the USA and fully custom-built. Contact us today for a free quote and tailored solution!

Packaging Line with Product Transfer System

Packaging Line with Product Transfer System

We can build a complete packaging line tailored to your requirements, including: Product Loader, Incline Conveyor, BESSEN T2 Product Transfer System, Combination Scale, Denester Machine, Tray Filling Module, Labeling Unit, and Conveyor System. All equipment is proudly made in the USA and fully custom-built. The line can be modified to meet your specific product, space, and speed requirements. Contact us today for a free quote!

PACKAGING EQUIPMENT BY PRODUCT GROUP

READY & FROZEN FOODS

READY & FROZEN FOOD

Recommended Equipment for Ready & Frozen Foods:

Spiral Chiller-Freezer – Ideal for quickly freezing items like shrimp, ravioli, or meat portions to preserve texture and extend shelf life.

Incline Conveyors – Move frozen or chilled foods—such as fillets, dumplings, or vegetables—between processing and filling stations.

Combination Scales – Ensure precise portion control for products like frozen mixed seafood, nuggets, or ready-meal components.

VFFS Machines / Tray Sealing Machines / Pouch Filling Machines – Seal bags of vegetables, trays of lasagna, or pouches of frozen soup with high efficiency and hygiene.

Take-Away Conveyor – Transports sealed packs to inspection, boxing, or accumulation areas.

Metal Detectors – Protect against contamination in frozen food packs before distribution.

Working Platform – Provides safe and ergonomic access to elevated equipment like weighers and fillers.

Typical Packaging Process:

Transfer → Freezing → Weighing → Filling → Sealing → Transfer (Optional: Labeling, Metal Detection)

From IQF vegetables and seafood mixes to frozen ready meals and raw proteins, Bessen's modular packaging systems help manufacturers boost productivity, meet hygiene standards, and scale operations efficiently.

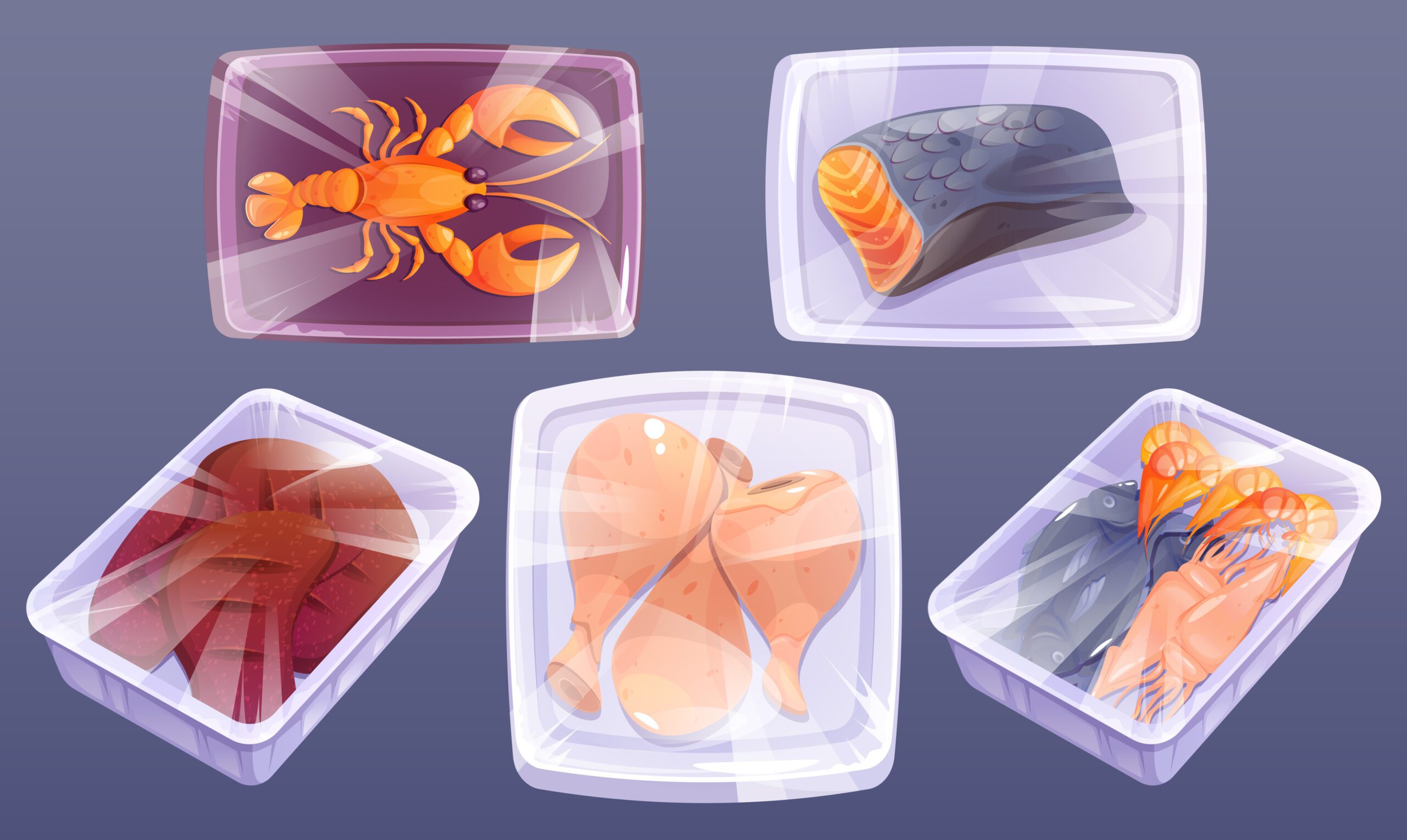

MEAT, FISH & SEAFOOD

MEAT, FISH & SEAFOOD

Recommended Equipment for Meat, Fish & Seafood:

Incline Conveyors – Efficiently transport proteins and seafood to weighing or filling stations.

Combination Scales – Provide precise portion control for meats, fish fillets, or mixed seafood.

Tray Sealing Machines / VFFS Machines / Pouch Filling Machines – Flexible systems for sealing trays, bags, or pouches with meat, seafood, or mixed protein products.

Take-Away Conveyor – Moves filled and sealed packages downstream for further handling or inspection.

Metal Detectors – Detect and prevent contamination in packaged meat and seafood.

Working Platform – Enables operator access to elevated filling and weighing equipment for safe and efficient operation.

Typical Packaging Process:

Transfer → Weighing → Filling → Sealing → Transfer (Optional: Labeling, Metal Detection, Vacuuming)

Our modular, stainless-steel systems are designed for durability and sanitation in cold, wet environments. Whether you're packaging vacuum-sealed steak cuts, VFFS-packed shrimp, or tray-sealed fish fillets, Bessen equipment is built to support high-throughput protein packaging lines while meeting strict hygiene standards.

SNACKS & SWEETS

SNACKS & SWEETS

Recommended Equipment for Snacks & Sweets Packaging:

Incline Conveyors – Gently transport loose or delicate snack items to weighing or filling stations.

Combination Scales – Deliver fast and precise portioning for mixed candies, chips, baked snacks, and other lightweight products.

Tray Sealing Machines / VFFS Machines / Pouch Filling Machines / Horizontal Flow Wrappers – Flexible options to package snacks in trays, vertical bags, resealable pouches, or flow-wrapped packs for bars and baked goods.

Take-Away Conveyor – Transfers sealed snack packages to labeling, inspection, or boxing areas.

Metal Detectors – Critical for ensuring product safety by detecting foreign materials before shipment.

Working Platform – Provides secure operator access to combination scales and filling equipment for streamlined operation and maintenance.

Typical Packaging Process: Transfer → Weighing → Filling → Sealing → Transfer (Optional: Labeling, Metal Detection)

From individually wrapped snack bars to resealable pouches of cookies or candy, Bessen's stainless-steel packaging systems are built for food-grade environments where speed, sanitation, and visual appeal are key. Our solutions support high-volume output, fast product changeovers, and seamless integration into modern snack production lines.

FRUITS, VEGETABLES & GRAINS

FRUITS, VEGETABLES & GRAINS

Recommended Equipment for Fresh Fruits, Vegetables & Grains:

Incline Conveyors – Gently transport loose or fragile fresh produce to weighing and filling stations.

Combination Scales – Ensure precise portioning of products like fresh grapes, mixed greens, or grains.

Tray Sealing Machines / VFFS Machines / Pouch Filling Machines / Horizontal Flow Wrappers – Versatile options for sealing clamshell trays, pillow bags, stand-up pouches, and flow-wrapped produce items like mini cucumbers or snack packs.

Take-Away Conveyor – Moves sealed packages to labeling, inspection, or boxing stations.

Metal Detectors – Provide food safety assurance by identifying contaminants in produce and grain packs.

Working Platform – Offers ergonomic access to multihead weighers and filling systems for streamlined operation.

Typical Packaging Process: Transfer → Weighing → Filling → Sealing → Transfer (Optional: Labeling, Metal Detection)

From fresh fruit trays and grain pouches to flow-wrapped vegetable snack packs, Bessen’s stainless-steel packaging systems are ideal for food-grade environments. Our solutions are built for durability, hygiene, and flexibility, offering fast changeovers and smooth integration into automated production lines.

NUTS, DRIED FRUITS & SUPPLEMENTS

NUTS, DRIED FRUITS & SUPPLEMENTS

Recommended Equipment for Nuts, Dried Fruits & Supplements:

Incline Conveyors – Gently move free-flowing products to weighing or filling stations with minimal breakage.

Combination Scales – Ensure accurate weight control for small, lightweight items like nuts, berries, or tablets.

Tray Sealing Machines / VFFS Machines / Pouch Filling Machines – Versatile sealing and filling options for trays, pillow bags, stand-up pouches, and sachets.

Take-Away Conveyor – Transports sealed products for final packaging, inspection, or labeling.

Metal Detectors – Protect consumer safety by detecting foreign objects in nut or supplement packs.

Working Platform – Provides operator access for servicing and monitoring equipment at elevated levels.

Typical Packaging Process: Transfer → Weighing → Filling → Sealing → Transfer (Optional: Labeling, Metal Detection)

Whether you're filling snack-size nut pouches, bulk dried fruit bags, or branded supplement containers, Bessen equipment is built for speed, sanitation, and precision. Our stainless-steel, modular systems are ideal for food-grade and nutraceutical environments, offering seamless integration and fast changeovers to meet evolving production needs.

PET FOOD & TREATS

PET FOOD & TREATS

Recommended Equipment for Pet Food & Treats Packaging:

Incline Conveyors – Move dry or semi-moist pet food products efficiently to weighing or filling stations.

Combination Scales – Deliver accurate, multi-head weighing for pet treats, dry food, or supplements.

Tray Sealing Machines / VFFS Machines / Pouch Filling Machines / Horizontal Flow Wrappers – Versatile equipment options for sealing trays, vertical bags, stand-up pouches, and individually wrapped treats.

Take-Away Conveyor – Transfers filled and sealed pet food packages downstream for further inspection or boxing.

Metal Detectors – Enhance product safety by detecting contaminants in dry pet food or treat packaging.

Working Platform – Provides ergonomic access for operators to service and monitor weighers and filling systems.

Typical Packaging Process: Transfer → Weighing → Filling → Sealing → Transfer (Optional: Labeling, Metal Detection)

Whether you're producing individually wrapped chew sticks, bulk kibble bags, or multi-pack pet treat pouches, Bessen’s stainless-steel packaging equipment is built for sanitation, flexibility, and long-term reliability. Our solutions integrate seamlessly into automated production environments and offer fast changeovers for varied product lines.

INDUSTRIAL & HARDWARE

INDUSTRIAL & HARDWARE PRODUCTS

Recommended Equipment for Industrial & Hardware Packaging:

Incline Conveyors – Reliably transport heavy or small loose parts to the weighing or filling stations.

Combination Scales – Ensure precise counting and weight control for items like screws, washers, or metal fittings.

VFFS Machines / Pouch Filling Machines – Flexible options for packaging industrial parts into vertical bags or durable stand-up pouches.

Take-Away Conveyor – Moves sealed packs to labeling, bundling, or final boxing areas.

Working Platform – Offers safe and ergonomic access to weighers and fillers for system maintenance and operation.

Typical Packaging Process: Transfer → Weighing → Filling → Sealing → Transfer (Optional: Labeling)

Whether you're packaging hardware kits, bulk fasteners, or individual components, Bessen's stainless-steel, modular packaging systems are built to withstand tough production environments while maintaining accuracy and speed. Designed for integration into automated production lines, our solutions support both high-volume runs and flexible small-batch operations.

BEVERAGES & LIQUIDS

BEVERAGES & LIQUIDS

Recommended Equipment for Beverages & Liquids Packaging:

VFFS Machines – Liquid Models – Form, fill, and seal pouches or sachets with liquid products using specialized no-drip technology.

Pouch Filling Machines – Liquid Models – Ideal for stand-up pouches or spouted bags, ensuring mess-free and consistent fill volumes.

Smart Filling Lines – High-speed, multi-nozzle systems for filling bottles, jars, or pouches with beverages or viscous liquids.

Take-Away Conveyor – Transfers sealed containers for downstream labeling, inspection, or packing.

Metal Detectors – Enhance product safety by detecting contaminants in sealed liquid packaging before distribution.

Typical Packaging Process: Filling → Bag/Bottle Sealing → Transfer (Optional: Labeling, Metal Detection)

From single-serve drink pouches to multi-liter bottles of sauces or oils, Bessen’s liquid packaging equipment is designed for cleanability, performance, and flexibility. Built from stainless steel and optimized for sanitation, our systems are ideal for food-grade, nutraceutical, and specialty drink production environments.

Hours of Operation

MON – FRI

8:30am – 6:00pm

SAT

9:00am – 3:30pm

SUN

We are closed

Drop Us a Line

Don’t be shy. Let us know if you have any questions!